Safety and Risk

Over the years, Fluidyn has developed a unique expertise in the fields of safety and industrial risk management. Thanks to its various software tools dedicated to consequence modelling, Fluidyn offers a broad array of simulation services for the assessment of accidental scenarios in open as well as confined environments.

Following our many years of experience, our consultancy teams can help you identify the hazards of your facility, model accurately and in a realistic way the consequences of major accidents, analyze risks, optimize safety areas and improve the overall risk management performance of your company. Thanks to the panel of 3D numerical simulation solutions in our reach, our consultants can explore in detail your problem and offer you the assistance you need.

Fluidyn has the ability to assist you on the following topics:

Dispersion modelling

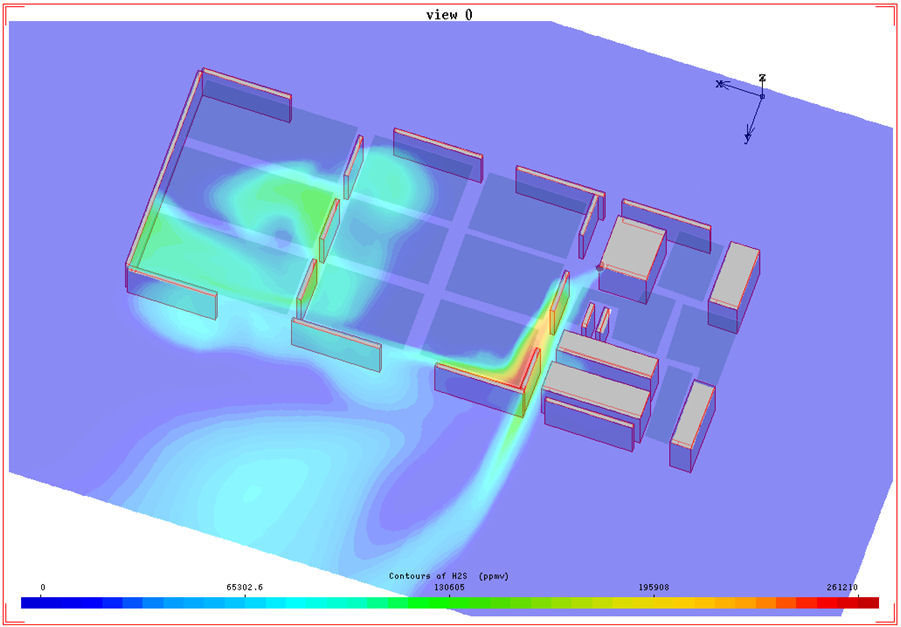

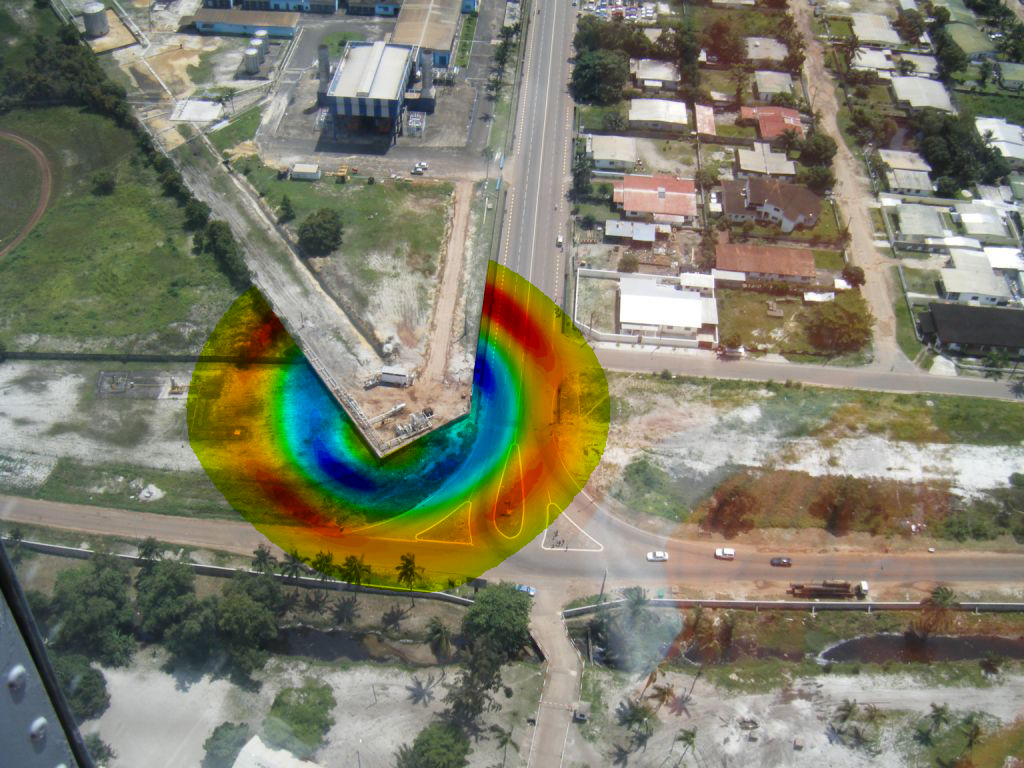

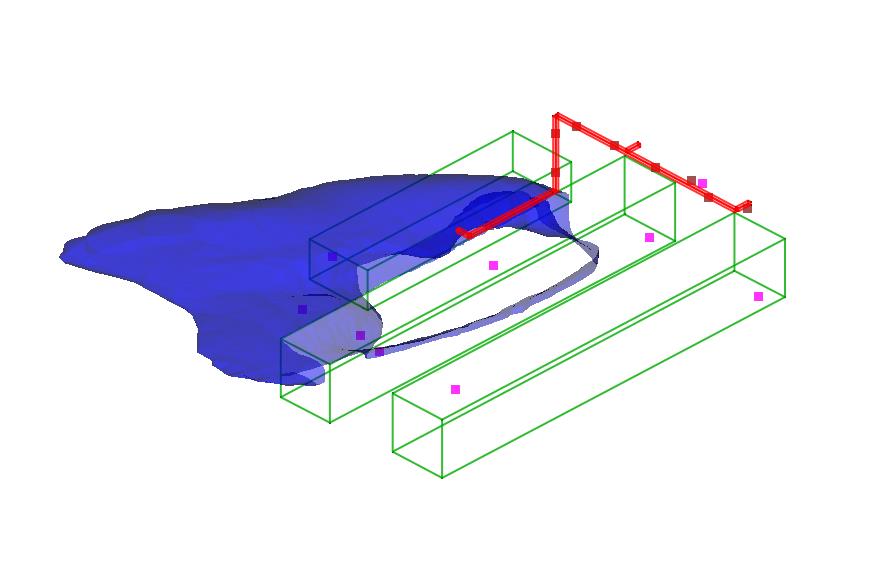

A large number of industrial accidents start as a leak of a toxic or flammable gas in atmosphere. Controlling the risk involves the right assessment of the extent of the gas cloud from any leaking equipment or storage tank for both onsite and offsite effects. We can help you in assessing the hazardous consequence of toxic and flammable release with our abilities in 3D dispersion modelling in complex geometries. Our high-experienced consultants will ensure you the best approach for your dispersion case studies in the following fields:

- Flammable gas dispersion

- Toxic gas dispersion

- Radionuclides dispersion

- Safety measures design and performance analysis

- Gas sensor layout optimization (smoke, toxic gas, flammable gas)

- Leaks identification by inverse modeling

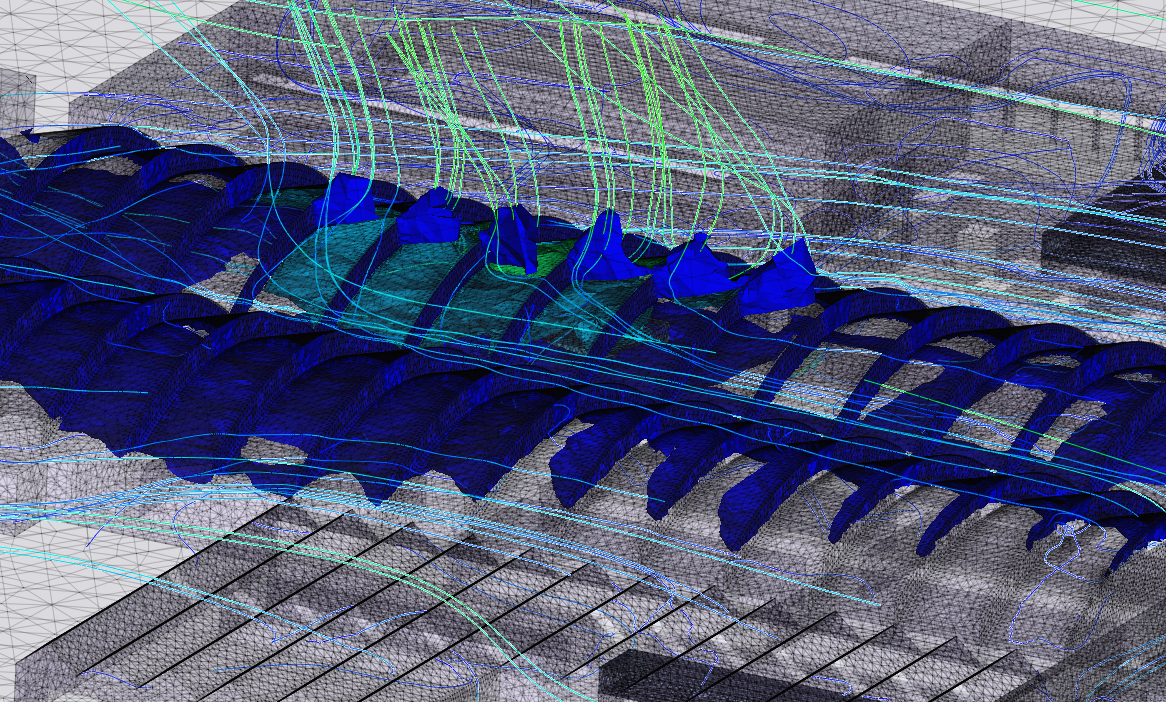

Explosion modelling

Gas or dust explosion is one of the most critical accidents on a onshore plant or offshore facilities. Our consultancy team can help you in the consequence assessment of the overpressures caused by all kind of explosion scenarios in simple or more complex geometries. Our experience and knowledge in explosion modelling give you the opportunity to perform the following studies:

- Gas explosion and deflagration including hydrogen

- Solid explosive detonation

- Blast propagation

- Blast wave load on structure

- Dust explosion

- Influence of the ignition points

- Explosion mitigation measures design and ALARP analysis

- Accident investigations

Fire modelling

Fire modelling is used to assess the heat radiation and the spread of smoke from solid or liquid fires. Our experts with their knowledge of simulation tools can assess and improve the fire safety of your facilities and help you in the following fields:

- Flammable liquid, solid or jet fires simulation

- Fires of various natures (pools, rack, bulk, warehouses, offshore platforms, car parks, fires in buildings…)

- Structural integrity analysis for thermal load

- Smoke dispersion inside and outside buildings

- Toxicity and visibility assessment of smoke propagation

- Fire mitigation measures design

- Accident investigations

Find additionnal informations on our dedicated softwares Fluidyn-PANFIRE and Fluidyn-VENTFIRE

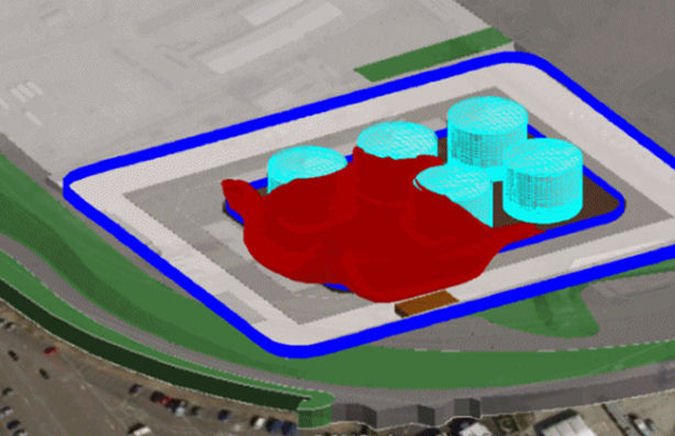

Tank rupture modelling

Tank rupture modelling is used to assess the overflow following a loss of containment through a catastrophic tank failure. Our modelling experts can assess the potential consequences of :

- Overspill of Flammable Liquids,

- Pool spreading inside the retention

- Liquid behaviour outside the retention and impacted areas,

- Pressure loads on retention bunds and walls,

- Structural integrity analysis of bunds and walls,

- Mitigation measures design (secondary confinement, wall shape, wave breaker, …)

- Accident investigations

Process safety and risk analysis

The risk assessment based on the prevailing regulations is done step by step from the potential hazard identification to the final risk analysis. The objective of the risk assessment of your facilities is to reduce and manage risk by including the operational safety to the environment protection without neglecting the cost aspects. Our high capability consultancy team can help you in your risk analysis from the hazardous inventory (HAZID) to the quantitative risk assessment (QRA).

- Hazard identification and analysis

- Consequence modelling

- Risk analysis (preliminary risk analysis, fault tree, bow tie, …)

- Quantitative risk assessment (QRA)

- Optimization of mitigation measures performance (fire walls, blast walls, toxic/flammable detection,…) by numerical modelling

Sensor network optimization

The gas sensor network is one of the most important safety features on an industrial plant. Ensuring that the network is well designed and efficient reduces greatly the major accidents related to toxic/flammable releases on your facilities. Our engineering team can help you in optimizing your sensor layout (location, number, specifications…) with an appropriate strategy based on dispersion modeling and inverse calculation for any kind of gas release in complex geometries.

- Optimization of sensor locations

- Performance analysis of an existing sensor network

- Improvement of the efficiency with new threshold alarm value

- Cost reduction by redundant sensor removing

Find informations on our dedicated software Fluidyn-PANACHE

Post accident analysis

Our consultants with high experience in accident modelling, ranging from toxic release to large fires and explosions, can assist plant owners and mandatory authorities in understanding the cause and consequences of major accidents.

Fluidyn can also be part of legal investigations providing our expertise. Based on the investigation of incident consequences, our team can perform simulations to identify the origin and the factors leading of the accident. With our consequence modelling expertise, we can assess accurately the fire products dispersion and the overpressure effects during the unfolding of the accident as well as the impacted surrounding areas. Theses investigations will give you new solutions to improve the risk management of your facilities.