Furnace deformation due to thermal stress

Context and objectives

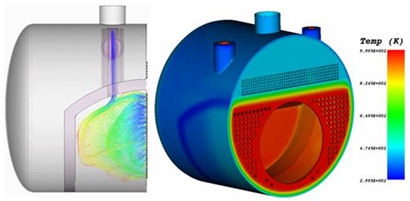

TOTAL asked for the structure behaviour analysis of a funace in a refinery unit. The objective is the causes identification of the refractory coating degradations in the chamber.

Our success

The coupled simulation of fluid-structure thermal transfers and the structure deformation (steel, concrete, refractory coating) in and between the hot and cold rooms and the elements supporting the arrivals and departures of the exchangers has been done in the 3D-CFD software Fluidyn-MP.

The simulations consistes in 3 different states / operating modes of the furnace:

- Stationary study (on the present design) for a nominal operating mode

- Dynamic study (on the present design) for critical boundary conditions (eg starting with natural gas after preheating but without injection of acid gas) for a situation out of thermal equilibrium.

- Dynamic study of the new system with new mechanical properties of materials.